Stanley Meyer: Water Fuel Cell

Electronics World & Wireless World

( January 1991)

USP # 4,936,961 ~ Method for the Production

of a Fuel Gas

KeelyNet/Vangard Notes

USP # 4,826,581 ~ Controlled Process for the

Production of Thermal Energy from Gases...

USP # 4,798,661 ~ Gas Generator Voltage Control

Circuit

USP # 4,613,304 ~ Gas Electrical Hydrogen

Generator

USP # 4,465,455

~ Start-up/Shut-down

for a Hydrogen Gas Burner

USP # 4,421,474 ~ Hydrogen Gas Burner

USP # 4,389,981 ~ Hydrogen Gas Injector System

for Internal Combustion Engine

Dan Danforth: Molecular Dissociation of Water

Water Fuel Cell News Release (Winter/Spring

87/88)

Raum & Zeit 1(6) 63-68 (1990)

Patents Granted (@ 1990)

Water Fuel Cell R&D Format

Infinite Energy 19: 50-51 (1998) Obituary

Water-Powered

Car Video ( Link to http://www.lonelantern.org/collection.html

)

Excerpts from: Electronics World & Wireless World

( January 1991) ~ KeelyNet File MEYER1.ASC

Eye-witness accounts suggest that US inventor Stanley Meyer has developed

an electric cell which will split ordinary tap water into hydrogen and

oxygen with far less energy than that required by a normal electrolytic

cell.

In a demonstration made before Professor Michael Laughton, Dean of Engineering

at Mary College, London, Admiral Sir Anthony Griffin, a former controller

of the British Navy, and Dr Keith Hindley, a UK research chemist.

Meyer's cell, developed at the inventor's home in Grove City, Ohio, produced

far more hydrogen/oxygen mixture than could have been expected by simple

electrolysis.

Where normal water electrolysis requires the passage of current measured

in amps, Meyer's cell achieves the same effect in milliamps. Furthermore,

ordinary tap water requires the addition of an electrolyte such as sulphuric

acid to aid current conduction; Meyer's cell functions at greatest efficiency

with pure water.

According to the witnesses, the most startling aspect of the Meyer cell

was that it remained cold, even after hours of gas production.

Meyer's experiments, which he seems to be able to perform to order,

have earned him a series of US patents granted under Section 101. The granting

of a patent under this section is dependent on a successful demonstration

of the invention to a Patent Review Board.

Meyer's cell seems to have many of the attributes of an electrolytic

cell except that it functions at high voltage, low current rather than

the other way around. Construction is unremarkable. The electrodes ---

referred to as "excitors" by Meyer --- are made from parallel plates of

stainless steel formed in either flat or concentric topography. Gas production

seems to vary as the inverse of the distance between them; the patents

suggest a spacing of 1.5 mm produces satisfactory results.

The real differences occur in the power supply to the cell. Meyer uses

an external inductance which appears to resonate with the capacitance of

the cell --- pure water apparently possesses a dielectric constant of about

5 --- to produce a parallel resonant circuit. This is excited by a high

power pulse generator which, together with the cell capacitance and a rectifier

diode, forms a charge pump circuit. High frequency pulses build a rising

staircase DC potential across the electrodes of the cell until a point

is reached where the water breaks down and a momentary high current flows.

A current measuring circuit in the supply detects this breakdown and removes

the pulse drive for a few cycles allowing the water to "recover".

Research chemist Keith Hindley offers this description of a Meyer cell

demonstration: "After a day of presentations, the Griffin committee witnessed

a number of important demonstration of the WFC" (water fuel cell as named

by the inventor).

A witness team of independent UK scientifc observers testified that

US inventor Stanley Meyer successfully decomposed ordinary tap water into

constituent elements through a combination of high, pulsed voltage using

an average current measured only in milliamps. Reported gas evolution was

enough to sustain a hydrogen /oxygen flame which instantly melted steel.

In contrast with normal high current electrolysis, the witnesses report

the lack of any heating within the cell. Meyer declines to release details

which would allow scientists to duplicate and evaluate his "water fuel

cell". However, he has supplied enough detail to the US Patent Office to

persuade them that he can substantiate his 'power-from-water' claims.

One demonstration cell was fitted with two parallel plate "excitors".

Using tap water to fill the cell, the plates generated gas at very low

current levels --- no greater than a tenth of an amp on the ammeter, and

claimed to be milliamps by Meyer --- and this gas production increased

steadily as the plates were moved closer together and decreased as they

were separated. The DC voltage appeared to be pulsed at tens of thousands

of volts.

A second cell carried nine stainless steel double tube cell units and

generated much more gas. A sequence of photographs was taken showing gas

production at milliamp levels. When the voltage was turned up to its peak

value, the gas then poured off at a very impressive level.

"We did notice that the water at the top of the cell slowly became discolored

with a pale cream and dark brown precipitate, almost certainly the effects

of the chlorine in the heavily chlorinated tap water on the stainless steel

tubes used as "excitors".

He was demonstrating hydrogen gas production at milliamp and kilovolt

levels.

"The most remarkable observation is that the WFC and all its metal pipework

remained quite cold to the touch, even after more than twenty minutes of

operation. The splitting mechanism clearly evolves little heat in sharp

contrast to electrolysis where the electrolyte warms up quickly."

"The results appear to suggest efficient and controllable gas production

that responds rapidly to demand and yet is safe in operation. We clearly

saw how increasing and decreasing the voltage is used to control gas production.

We saw how gas generation ceased and then began again instantly as the

voltage driving circuit was switched off and then on again."

"After hours of discussion between ourselves, we concluded that Stan

Meyer did appear to have discovered an entirely new method for splitting

water which showed few of the characteristics of classical electrolysis.

Confirmation that his devices actually do work come from his collection

of granted US patents on various parts of the WFC system. Since they were

granted under Section 101 by the US Patent Office, the hardware involved

in the patents has been examined experimentally by US Patent Office experts

and their seconded experts and all the claims have been established."

"The basic WFC was subjected to three years of testing. This raises

the granted patents to the level of independent, critical, scientific and

engineering confirmation that the devices actually perform as claimed."

The practical demonstration of the Meyer cell appears substantially

more convincing than the para-scientific jargon which has been used to

explain it. The inventor himself talks about a distortion and polarization

of the water molecule resulting in the H:OH bonding tearing itself apart

under the electrostatic potential gradient, of a resonance within the molecule

which amplifies the effect.

Apart from the copious hydrogen/oxygen gas evolution and the minimal

temperature rise within the cell, witnesses also report that water within

the cell disappears rapidly, presumably into its component parts and as

an aerosol from the myriad of tiny bubbles breaking the surface of the

cell.

Meyer claims to have run a converted VW on hydrogen/oxygen mixture for

the last four years using a chain of six cylindrical cells. He also claims

that photon stimulation of the reactor space by optical fibre piped laser

light increases gas production.

The inventor is a protegee' of the Advanced Energy Institute.

USP # 4,936,961

Method for the Production of a Fuel Gas

Stanley Meyer

Related Application: This is a continuation-in-part of my co-pending

application Ser.; No. 081,859, filed 8/5/87, now U.S. Pat. No. 4,826, 581.

Field of Invention: This invention relates to a method of and apparatus

for obtaining the release of a fuel gas mixture including hydrogen and

oxygen from water.

BACKGROUND OF THE PRIOR ART

Numerous processes have been proposed for separating a water molecule

into its elemental hydrogen and oxygen components. Electrolysis is one

such process. Other processes are described in the United States patents

such as 4,344,831; 4,184,931; 4,023,545; 3,980, 053; and Patent Cooperation

Treaty application No. PCT/US80/1362, Published 30 April, 1981.

OBJECTS OF THE INVENTION

It is an object of the invention to provide a fuel cell and a process

in which molecules of water are broken down into hydrogen and oxygen gases,

and other formerly dissolved within the water is produced. As used herein

the term "fuel cell" refers to a single unit of the invention comprising

a water capacitor cell, as hereinafter explained, that produces the fuel

gas in accordance with the method of the invention.

Brief Description of the Drawings

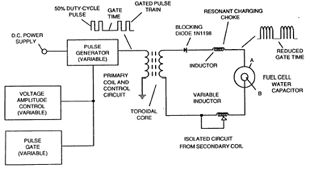

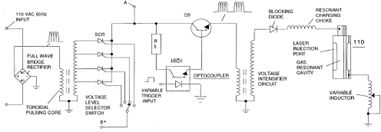

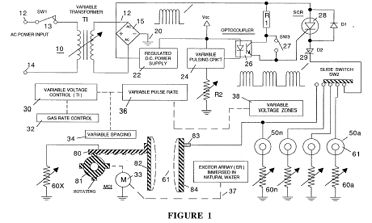

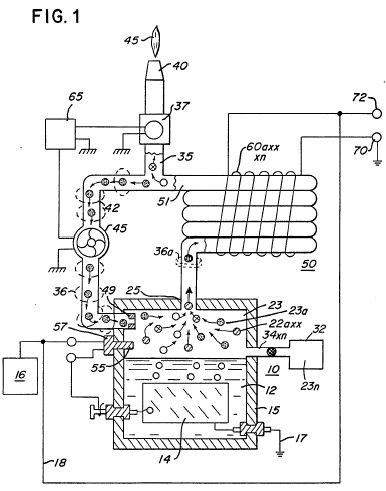

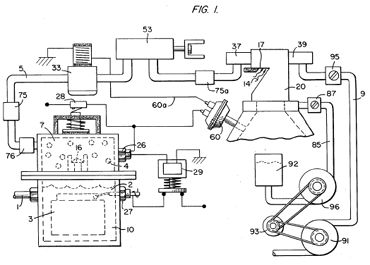

FIG. 1 illustrates a circuit useful in the process.

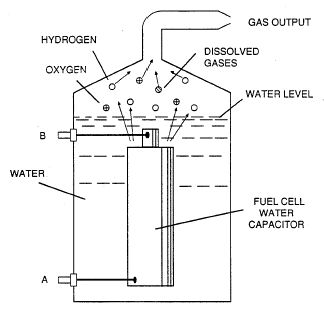

FIG. 2 shows a perspective of a "water capacitor" element used in the

fuel cell circuit.

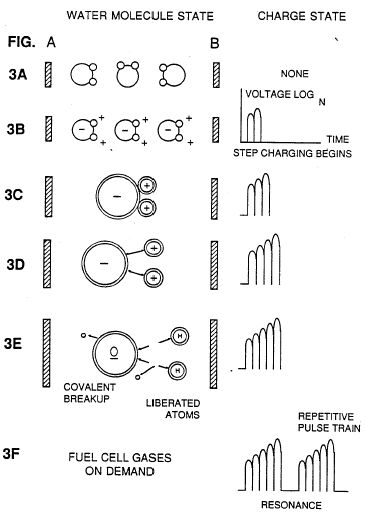

FIGS. 3A through 3F are illustrations depicting the theoretical bases

for the phenomena encountered during operation of the invention herein.

Description of the Preferred Embodiment:

In brief, the invention is a method of obtaining the release of a gas

mixture including hydrogen on oxygen and other dissolved gases formerly

entrapped in water, from water consisting of:

(A) providing a capacitor, in which the water is included as a dielectric

liquid between capacitor plates, in a resonant charging choke circuit that

includes an inductance in series with the capacitor;

(B) subjecting the capacitor to a pulsating, unipolar electric voltage

field in which the polarity does not pass beyond an arbitrary ground, whereby

the water molecules within the capacitor are subjected to a charge of the

same polarity and the water molecules are distended by their subjection

to

electrical polar forces;

(C) further subjecting in said capacitor to said pulsating electric

field to achieve a pulse frequency such that the pulsating electric field

induces a resonance within the water molecule;

(D) continuing the application of the pulsating frequency to the capacitor

cell after resonance occurs so that the energy level within the molecule

is increased in cascading incremental steps in proportion to the number

of pulses;

(E) maintaining the charge of said capacitor during the application

of the pulsing field, whereby the co-valent electrical bonding of the hydrogen

and oxygen atoms within said molecules is destabilized such that the force

of the electrical field applied, as the force is effective within the molecule,

exceeds the bonding force of the molecule, and hydrogen and oxygen atoms

are liberated from the molecule as elemental gases; and

(F) collecting said hydrogen and oxygen gases, and any other gases that

were formerly dissolved within the water, and discharging the collected

gases as a fuel gas mixture.

The process follows the sequence of steps shown in the following Table

1 in which water molecules are subjected to increasing electrical forces.

In an ambient state, randomly oriented water molecules are aligned with

respect to a molecule polar orientation.

They are next, themselves polarized and "elongated" by the application

of an electrical potential to the extent that covalent bonding of the water

molecule is so weakened that the atoms dissociate and the molecule breaks

down into hydrogen and oxygen elemental components.

Engineering design parameters based on known theoretical principles

of electrical circuits determine the incremental levels of electrical and

wave energy input required to produce resonance in the system whereby the

fuel gas comprised of a mixture of hydrogen, oxygen, and other gases such

as air were formerly dissolved within the water, is produced.

TABLE 1

Process Steps:

The sequence of the relative state of the water molecule and/or hydrogen/oxygen/other

atoms:

A. (ambient state) random

B. Alignment of polar fields

C. Polarization of molecule

D. Molecular elongation

E. Atom liberation by breakdown of covalent bond

F. Release of gases

In the process, the point of optimum gas release is reached at a circuit

resonance. Water in the fuel cell is subjected to a pulsating, polar electric

field produced by the electrical circuit whereby the water molecules are

distended by reason of their subjection to electrical polar forces of the

capacitor plates.

The polar pulsating frequency applied is such that the pulsating electric

field induces a resonance in the molecule. A cascade effect occurs and

the overall energy level of specific water molecules is increased in cascading,

incremental steps.

The hydrogen and oxygen atomic gases, and other gas components formerly

entrapped as dissolved gases in water, are released when

the resonant energy exceeds the covalent bonding force of the water

molecule. A preferred construction material for the capacitor plates

is stainless steel T-304 which is non-chemical reactive with

water, hydrogen, or oxygen.

An electrically conductive material which is inert in the fluid environment

is a desirable material of construction for the electrical field plates

of the "water capacitor" employed in the circuit.

Once triggered, the gas output is controllable by the attenuation of

operational parameters. Thus, once the frequency of resonance is identified,

by varying the applied pulse voltage to the water fuel cell assembly, gas

output is varied.

By varying the pulse shape and/or amplitude or pulse train sequence

of the initial pulsing wave source, final gas output is varied. Attenuation

of the voltage field frequency in the form of OFF and ON pulses likewise

affects output.

The overall apparatus thus includes an electrical circuit in which a

water capacitor having a known dielectric property is an element. The fuel

gases are obtained from the water by the disassociation of the water molecule.

The water molecules are split into component atomic elements (hydrogen

and oxygen gases) by a voltage stimulation process called the electrical

polarization process which also releases dissolved gases entrapped in the

water.

From the outline of physical phenomena associated with the process described

in Table 1, the theoretical basis of the invention considers the respective

states of molecules and gases and ions derived from liquid water.

Before voltage stimulation, water molecules are randomly dispersed throughout

water in a container.

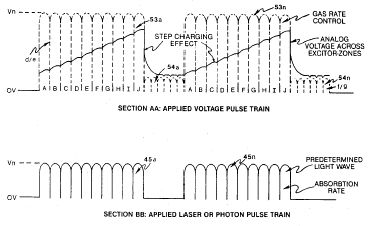

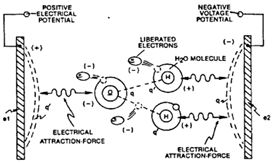

When a unipolar voltage pulse train such as shown in FIGS. 3B through

3F is applied to positive and negative capacitor plates, an increasing

voltage potential is induced in the molecules in a linear, step like charging

effect.

The electrical field of the particles within a volume of water including

the electrical field plates increases from a low energy state to a high

energy state successively is a step manner following each pulse-train as

illustrated figuratively in the depictions of FIG. 3A through 3F.

The increasing voltage potential is always positive in direct relationship

to negative ground potential during each pulse. The voltage polarity on

the plates which create the voltage fields remains constant although the

voltage charge increases. Positive and negative voltage "zones" are thus

formed simultaneously in the electrical field of the capacitor plates.

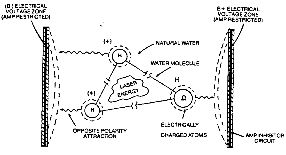

In the first stage of the process described in Table 1, because the

water molecule naturally exhibits opposite electrical fields in a relatively

polar configuration (the two hydrogen atoms are positively electrically

charged relative to the negative electrically charged oxygen atom), the

voltage pulse causes initially randomly oriented water molecules in the

liquid state to spin and orient themselves with reference to positive

and negative poles of the voltage fields applied.

The positive electrically charged hydrogen atoms of said water molecule

are attracted to a negative voltage field; while, at the same time, the

negative electrically charged oxygen atoms of the same water molecule are

attracted to a positive voltage field.

Even a slight potential difference applied to inert, conductive plates

of a containment chamber which forms a capacitor will initiate polar atomic

orientation within the water molecule based on polarity differences.

When the potential difference applied causes the orientated water molecules

to align themselves between the conductive plates, pulsing causes the voltage

field intensity to be increased in accordance with FIG. 3B. As further

molecule alignment occurs, molecular movement is hindered.

Because the positively charged hydrogen atoms of said aligned molecules

are attracted in a direction opposite to the negatively charged oxygen

atoms, a polar charge alignment or distribution occurs within the molecules

between said voltage zones, as shown in FIG. 3B. And as the energy level

of the atoms subjected to resonant pulsing increases, the stationary water

molecules become elongated as shown in FIGS. 3C and 3D. Electrically charged

nuclei and electrons are attracted toward opposite electrically charged

equilibrium of the water molecule.

As the water molecule is further exposed to an increasing potential

difference resulting from the step charging of the capacitor, the electrical

force of attraction of the atoms within the molecule to the capacitor plates

of the chamber also increase in strength. As a result, the covalent bonding

between which form the molecule is weakened --- and ultimately terminated.

The negatively charged electron is attracted toward the positively charged

hydrogen atoms, while at the same time, the negatively charged oxygen atoms

repel electrons.

In a more specific explanation of the "sub-atomic" action the occurs

in the water fuel cell, it is known that natural water is a liquid which

has a dielectric constant of 78.54 at 20 degrees C. and 1 atm pressure.

[Handbook of Chemistry & Physics, 68th ed., CRC Press(Boca Raton, Florida

(1987-88)), Section E-50. H20(water)].

When a volume of water is isolated and electrically conductive plates,

that are chemically inert in water and are separated by a distance, are

immersed in water, a capacitor is formed, having a capacitance determined

by the surface area of the plates, the distance of their separation and

the dielectric constant of water.

When water molecules are exposed to voltage at a restricted current,

water takes on an electrical charge. By the laws of electrical attraction,

molecules align according to positive and negative polarity fields of the

molecule and the alignment field. The plates of the capacitor constitute

such as alignment field when a voltage is applied.

When a charge is applied to a capacitor, the electrical charge of the

capacitor equals the applied voltage charge; in a water capacitor, the

dielectric property of water resists the flow of amps in the circuit, and

the water molecule itself, because it has polarity fields formed by the

relationship of hydrogen and oxygen in the covalent bond, and intrinsic

dielectric property, becomes part of the electrical circuit, analogous

to a "microcapacitor" within the capacitor defined by the plates.

In the Example of a fuel cell circuit of FIG. 1, a water capacitor is

included. The step-up coil is formed on a conventional toroidal core formed

of a compressed ferromagnetic powered material that will not itself become

permanently magnetized, such as the trademarked "Ferramic 06# "Permag"

powder as described in Siemens Ferrites Catalog, CG-2000-002-121, (Cleveland,

Ohio) No. F626-1205". The core is 1.50 inch in diameter and 0.25 inch in

thickness. A primary coil of 200 turns of 24 gauge copper wire is provided

and coil of 600 turns of 36 gauge wire comprises the secondary winding.

In the circuit of FIG 1, the diode is a 1N1198 diode which acts as a

blocking diode and an electric switch that allows voltage flow in one direction

only. Thus, the capacitor is never subjected to a pulse of reverse polarity.

The primary coil of the toroid is subject to a 50% duty cycle pulse.

The toroidal pulsing coil provides a voltage step-up from the pulse generator

in excess of five times, although the relative amount of step-up is determined

by preselected criteria for a particular application. As the stepped-up

pulse enters first inductor (formed from 100 turns of 24 gauge wire 1 inch

in diameter), an electromagnetic field is formed around the inductor, voltage

is switched off when the pulse ends, and the field collapses and produces

another pulse of the same polarity i.e., another positive pulse is formed

where the 50% duty cycle was terminated. Thus, a double pulse frequency

is produced; however, in pulse train of unipolar pulses, there is a brief

time when pulses are not present.

By being so subjected to electrical pulses in the circuit of FIG. 1,

water confined in the volume that includes the capacitor plates takes on

an electrical charge that is increased by a step charging phenomenon occurring

in the water capacitor. Voltage continually increases (to about 1000 volts

and more) and the water molecules starts to elongate.

The pulse train is then switched off; the voltage across the water capacitor

drops to the amount of the charge that the water molecules have taken on,

i.e., voltage is maintained across the charged capacitor. The pulse train

is the reapplied.

Because a voltage potential applied to a capacitor can perform work,

the higher the voltage the higher the voltage potential, the more work

is performed by a given capacitor. In an optimum capacitor that is wholly

non-conductive, zero (0) current flow will occur across the capacitor.

Thus, in view of an idealized capacitor circuit, the object of

the water capacitor circuit is to prevent electron flow through the circuit,

i.e. such as occurs by electron flow or leakage through a resistive element

that produces heat.

Electrical leakage in the water will occur, however, because of some

residual conductivity and impurities or ions that may be otherwise present

in the water. Thus, the water capacitor is preferably chemically inert.

An electrolyte is not added to the water.

In the isolated water bath, the water molecule takes on charge, and

the charge increases. The object of the process is to switch off the covalent

bonding of the water molecule and interrupt the subatomic force, i.e. the

electrical force or electromagnetic force, that binds the hydrogen and

oxygen atoms to form a molecule so that the hydrogen and oxygen separate.

Because an electron will only occupy a certain electron shell (shells

are well known) the voltage applied to the capacitor affects the electrical

forces inherent in the covalent bond. As a result of the charge applied

by the plates, the applied force becomes greater than the force of the

covalent bonds between the atom of the water molecule; and the water molecule

becomes elongated. When this happens, the time share ratio of the

electron shells is modified.

In the process, electrons are extracted from the water bath; electrons

are not consumed nor are electrons introduced into the water bath by the

circuit as electrons are conventionally introduced in as electrolysis process.

There may nevertheless occur a leakage current through the water.

Those hydrogen atoms missing electrons become neutralized; atoms are

liberated from the water. The charged atoms and electrons are attracted

to the opposite polarity voltage zones created between the capacitor plates.

The electrons formerly shared by atoms in the water covalent bond are reallocated

such that neutral elemental gases are liberated.

In the process, the electrical resonance may be reached at all levels

of voltage potential. The overall circuit is characterized as a "resonant

charging choke" circuit which is an inductor in series with a capacitor

that produces a resonant circuit. [SAMS Modern Dictionary of Electronics,

Rudolf Garff, copyright 1984, Howard W. Sams & Co. (Indianapolis, Ind.),

page 859.]

Such a resonant charging choke is on each side of the capacitor. In

the circuit, the diode acts as a switch that allows the magnetic field

produced in the inductor to collapse, thereby doubling the pulse frequency

and preventing the capacitor from discharging. In this manner a continuous

voltage is produced across the capacitor plates in the water bath; and

the capacitor does not discharge. The water molecules are thus subjected

to a continuously charged field until the breakdown of the covalent

bond occurs.

As noted initially, the capacitance depends on the dielectric properties

of the water and the size and separation of the conductive elements forming

the water capacitor.

EXAMPLE 1

In an example of the circuit of FIG. 1 (in which other circuit element

specifications are provided above), two concentric cylinders 4 inches long

formed the water capacitor of the fuel cell in the volume of water. The

outside cylinder was 0.75 inch in outside diameter; the inner cylinder

was 0.5 inch in outside diameter.

Spacing from the outside of the inner cylinder to the inner surface

of the outside cylinder was 0.0625 inch. Resonance in the circuit was achieved

at a 26 volt applied pulse to the primary coil of the toroid at 0 KHz,

and the water molecules disassociated into elemental hydrogen and

oxygen and the gas released from the fuel cell comprised a mixture of hydrogen,

oxygen from the water molecule, and gases formerly dissolved in the water

such as the atmospheric gases or oxygen, nitrogen, and argon.

In achieving resonance in any circuit, as the pulse frequency is adjusted,

the flow of amps is minimized and the voltage is maximized to a peak. Calculation

of the resonance frequency of an overall circuit is determined by known

means; different cavities have a different frequency of resonance

dependant on parameters of the water dielectric, plate size, configuration

and distance, circuit inductors, and the like. Control of the production

of fuel gas is determined by variation of the period of time between

a train of pulses, pulse amplitude and capacitor plate size and configuration,

with corresponding value adjustments to other circuit components.

The wiper arm on the second conductor tunes the circuit and accommodates

to contaminants in water so that the charge is always applied to the capacitor.

The voltage applied determines the rate of breakdown of the molecule into

its atomic components. As water in the cell is consumed, it is replaced

by any appropriate means or control system.

Variations of the process and apparatus may be evident to those skilled

in the art.

What is claimed is:

1. A method of obtaining the release of a gas mixture including

hydrogen and oxygen and other dissolved gases formerly entrapped

in water, from water, consisting of: (A) providing a capacitor in which

water is included as a dielectric between capacitor plates, in a resonant

charging choke circuit that includes an inductance in

series with the capacitor;

(B) subjecting the capacitor to a pulsating, unipolar electric charging

voltage in which the polarity does not pass beyond an arbitrary ground,

whereby the water molecules within the capacitor plates;

(C) further subjecting the water in said capacitor to a pulsating electric

field resulting from the subjection of the capacitor to the charging voltage

such that the pulsating electric field induces a resonance within the water

molecules;

(D) continuing the application of the pulsating charging voltage to

the capacitor after the resonance occurs so that the energy level within

the molecules is increased in cascading incremental steps in proportion

to the number of pulses;

(E) maintaining the charge of said capacitor during the application

of the pulsating charge voltage, whereby the covalent electrical bonding

of the hydrogen and oxygen atoms within said molecules is destabilized,

such that the force of the electrical field applied to the molecules exceeds

the bonding force within the molecules, and the

hydrogen and oxygen atoms are liberated from the molecules as elemental

gases.

2. The method of claim 1 including the further steps of collecting

said liberated gases and any other gases that were formerly dissolved within

the water and discharging said collected gases as a fuel gas mixture.

Keelynet/Vangard Notes

1N1198 Diode is also a NTE 5995 or a ECG 5994. It is a 40A 600

PIV Diode (the 40A is over kill and may not be needed).

Stainless Steel "T304" is a type of weldable Stainless, but other types

should work the same. "T304" is just the more common type of Stainless

tubing available.

The outer tube figures out to be 3/4" 16 gauge (.060 "wall") tube (a

common size) cut to 4 inch length.

The inner tube figures out to be 1/2" 18 gauge (.049 "wall", this is

a common size for this tube, but the actual gauge cannot be figured from

this patent documentation, but this size should work) cut to 4 inch length.

You should also attach the two leads to the Stainless, using Stainless

solid rod (1/6 dia would do) and USE LEAD FREE SOLDER ! (you may

want the purified water that is returned to drink some day).

You also need to figure out a way to keep the two tubes separated from

each other. This could be done with small pieces of plastic. They cannot

block the flow of water into/out of the tubes.

It was not indicated if the inner tube is full of water or not. The

guess here is that it is full of water, and this doesn't effect the device

at all.

The Patent doesn't say but I would think that insulating the leads with

some type of tubing up to the tubes would be electrically correct (and

probably wouldn't hurt).

The pulse frequency was not printed, it is estimated from the size

of the coils and transformer that the frequency doesn't exceed 50 Mhz.

Don't depend on this being fact, it's just a educated guess.

The circuit to do this is not shown, just empty boxes. It's time to

get out your SCOPE and try things! Don't forget to share your results with

others ! GREED is why this type of thing never gets out into the world

to do some GOOD. If you want to make some money, make something PRACTICAL

that WORKS and that PEOPLE can use in their every day lives, then sell

it! Holding onto information like this only hurts ALL OF US !!

USP # 4,826,581

Controlled Process for the Production of Thermal Energy

from Gases and Apparatus Useful Therefore

Stanley Meyer

(May 2, 1989)

Abstract ~

A method of and apparatus for obtaining the release of energy from

a gas mixture including hydrogen and oxygen in which charged ions are stimulated

to an activated state, and then passed through a resonant cavity, where

successively increasing energy levels are achieved, and finally passed

to an outlet orifice to produce thermal explosive energy.

Inventors: Meyer; Stanley A. (3792 Broadway, Grove City, OH 43123)

Appl. No.: 081859 ~ Filed: August 5, 1987

Current U.S. Class: 204/157.41; 204/164 ~ Intern'l Class: C07G

013/00

Field of Search: 204/164,157.41,157.44

References Cited:U.S. Patent Documents ~

4,233,109 Nov., 1980 Nishizawa 204/164.

4,406,765 Sep., 1983 Higashi, et al. 204/164.

4,687,753 Aug., 1987 Fiato et al. 204/157.

4,695,357 Sep., 1987 Boussert 204/157.

Primary Examiner: Kalafut; Stephen J. ~

Attorney, Agent or Firm: Porter, Wright, Morris & Arthur

Claims ~

1. A method of obtaining the release of energy from a gas mixture including

hydrogen and oxygen consisting of: (A) providing a first gas mixture including

at least a portion of hydrogen and oxygen gases; (B) subjecting the gas

mixture to a pulsating, polar electric field whereby electrons of the gas

atoms are distended in their orbital fields by reason of their subjection

to electrical polar forces, at a frequency such that the pulsating electric

field induces a resonance with respect to an electron of the gas atom;

(C) cascading said gas atoms with respect to the pulsating electric field

such that the energy level of the resonant electron is increased in cascading

incremental steps; (D) ionizing said gas atoms; (E) subjecting the ionized

gas atoms to electromagnetic wave energy having a predetermined frequency

to induce a further election resonance in the ion, whereby the energy level

of the electron is successively increased; (F) extracting further electrons

from the resonating ions while such ions are in an increased energy state

to destabilize the nuclear and electron configuration of said ions; and

(G) subjecting the destabilized ions to thermal ignition.

2. An apparatus for obtaining the release of energy from a gas mixture

including hydrogen and oxygen consisting of successively interconnected:

(A) first means for providing a first gas mixture including at least a

portion of hydrogen and oxygen gas; (B) second means for providing a pulsating,

polar electric field to the gas mixture, whereby electrons of the gas atoms

are distended in their orbital fields by reason of their subjection to

electrical polar forces, at a frequency such that the pulsating electric

field induces a resonance with respect to an electron of the gas atom;

and the energy level of the resonant electron is increased in cascading,

incremental steps; (C) third means for providing a further electric field

to ionize said gas atoms; (D) an electromagnetic wave energy source for

subjecting the ionized gas atoms to wave energy of a predetermined frequency

to induce a further election resonance in the ion, whereby the energy level

of the electron is further successively increased; (E) an electron sink

for extracting electrons from the resonating ions while such ions are in

an increased energy state to destabilize the nuclear and electron configuration

of said ions; (F) fourth means for directing particle flow in a continuous

manner through the electric fields, wave energy source and electron sink

to a final orifice at which the destabilized ions are thermally ignited;

and (G) a final orifice at which the mixture initially provided by the

first means, after having passed through and been processed by the preceeding

means of the apparatus, is thermally ignited.

Description~

FIELD OF THE INVENTION

This invention relates to a method of and apparatus for obtaining the

release of energy from a gas mixture including hydrogen and oxygen in which

charged ions are stimulated to an actived state, and then passed through

a resonant cavity, where successively increasing energy levels are achieved,

and finally passed to an outlet orifice to produce thermal explosive energy.

BACKGROUND OF THE PRIOR ART

Processes have been proposed for many years in which controlled energy

producing reactions of atomic particles are expected to occur under "cold"

conditions. [See. e.q.. Rafelski, J. and Jones, S.E., "Cold Nuclear Fusion,"

Scientific American, July, 1987, page 84]. The process and apparatus described

herein are considered variations to and improvements in processes by which

energy is derived from excited atomic components in a controllable manner.

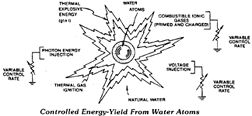

OBJECTS OF THE INVENTION

It is an object of the invention to realize significant energy-yield

from water atoms. Molecules of water are broken down into hydrogen and

oxygen gases. Electrically charged gas ions of opposite electrical polarity

are activated By Express Mail No. 26224690 on August 5, 1987 by electromagnetic

wave energy and exposed to a high temperature thermal zone. Significant

amounts of thermal energy with explosive force beyond the gas burning stage

are released.

An explosive thermal energy under a controlled state is produced. The

process and apparatus provide a heat energy source useful for power generation,

aircraft, rocket engines, or space stations.

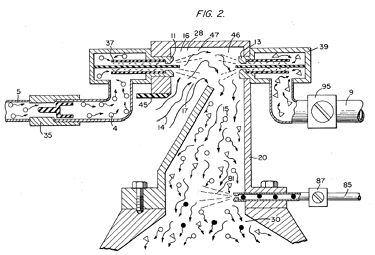

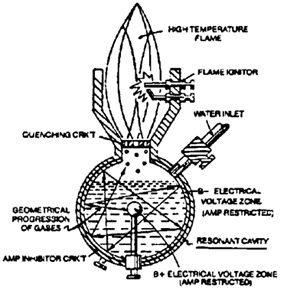

BRIEF DESCRIPTION OF THE DRAWINGS

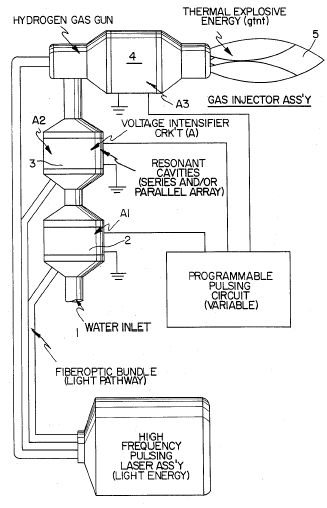

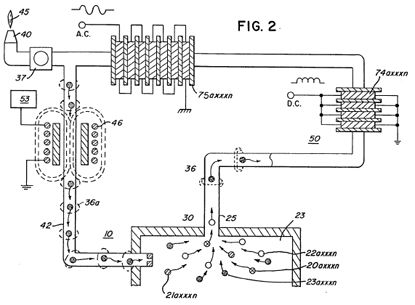

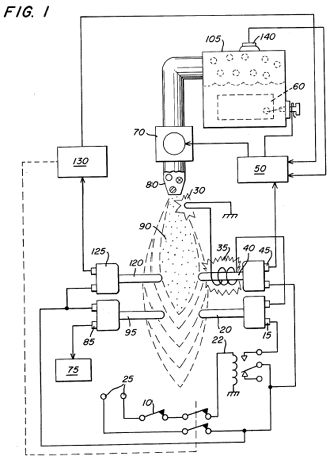

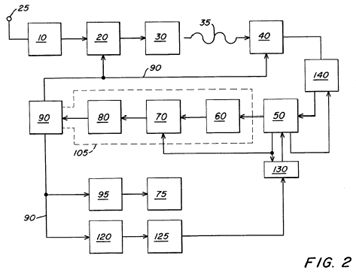

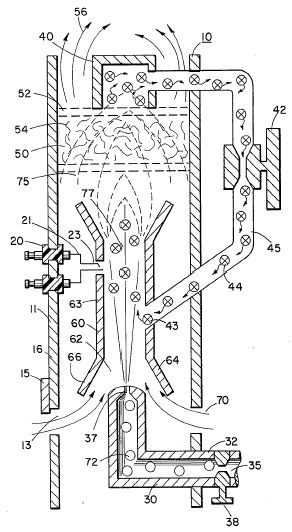

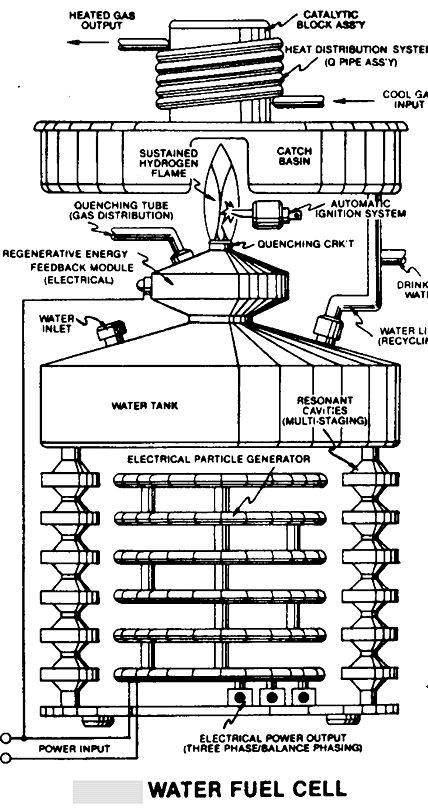

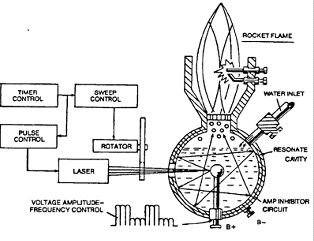

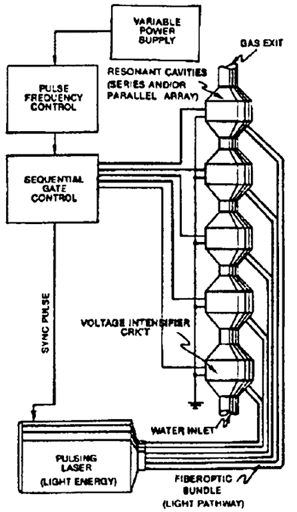

FIG. 1 illustrates a staged arrangement of apparatus useful in the process,

beginning with a water inlet and culminating in the production of thermal

explosive energy.

FIG. 2A shows a cross-section of a circular gas resonant cavity used

in the final stage assembly of FIG. 1.

FIG. 2B shows an alternative final stage injection system useful in

the apparatus of FIG. 1.

[Error in patent: Figure not shown]

FIG. 2C shows an optical thermal lens assembly for use either final

stage of FIG. 2A or FIG. 2B.

[Error in patent: Figure not shown]

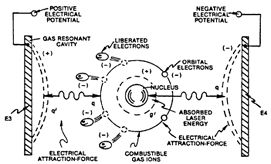

FIGS. 3A, 3B, 3C and 3D are illustrations depicting various theoretical

bases for atomic phenomena expected to occur during operation of the invention

herein.

[Error in patent: Figure not shown]

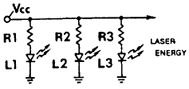

FIG. 4 is an electrical schematic of the voltage source for the gas

resonant cavity.

[Error in patent: Figure not shown]

FIGS. 5A and 5B, respectively, show (A) an electron extractor grid used

in the injector assemblies of FIG. 2A and FIG. 2B, and (B) the electronic

control circuit for the extractor grid.

[Error in patent: Figure not shown]

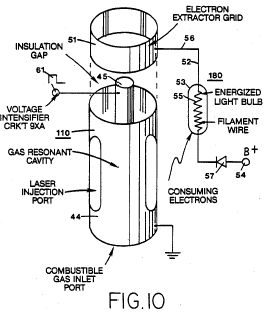

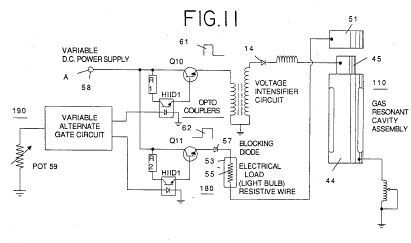

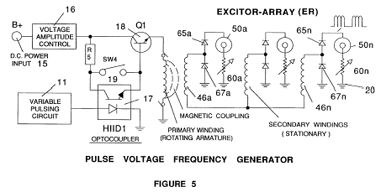

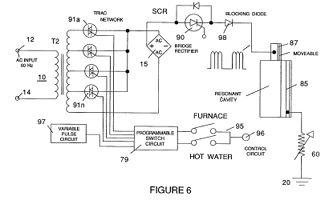

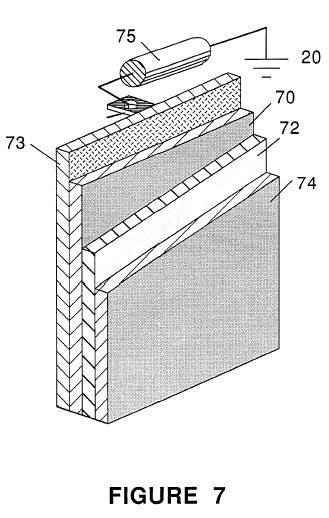

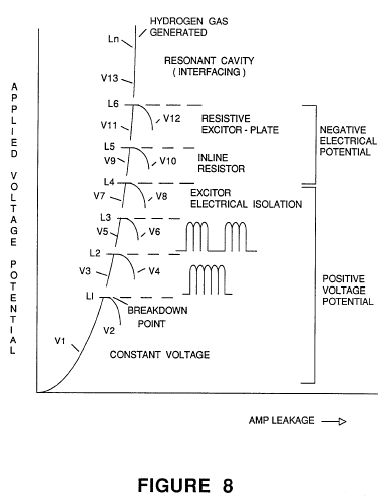

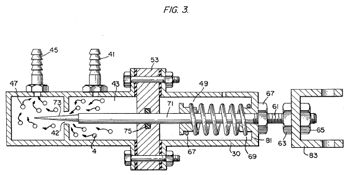

[Actual Figures: ]

Figure 3

.

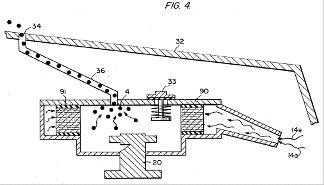

.

Figure 4

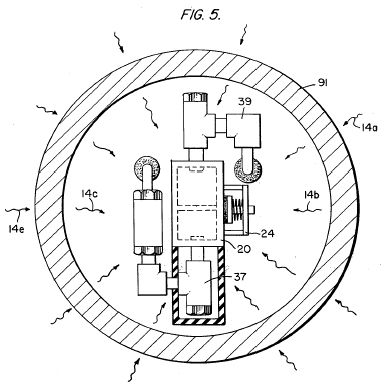

Figure 5

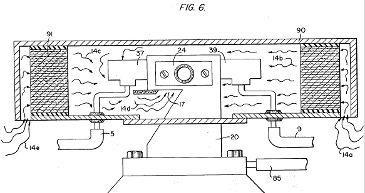

Figure 6

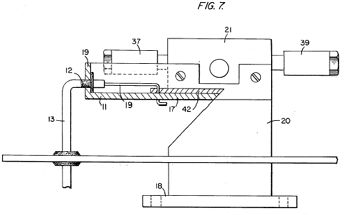

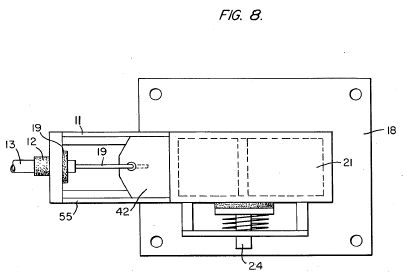

Figure 7

Figure 8

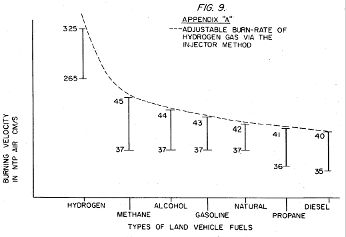

Figure 9

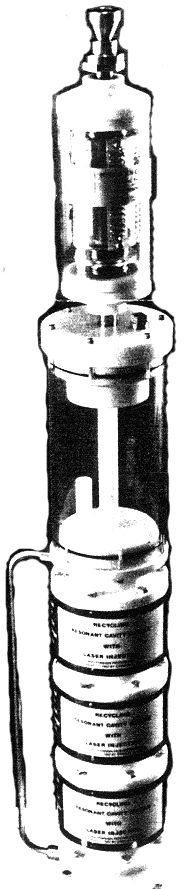

Figure 10

Figure 11

DESCRIPTION OF THE PREFERRED EMBODIMENT

The hydrogen fracturing process, follows the sequence of steps shown

in the following Table I in which beginning with water molecules, the molecule

is subjected to successively increasing electrical, wave energy and thermal

forces. In the succession of forces, radomly oriented water molecules are

aligned with respect to molecular polar orientation and are themselves

polarized and "elongated" by the application of an electric potential to

the extent that covalent bonding of the water molecule is so weakened that

the atoms disassociate and the molecule breaks down into hydrogen and oxygen

elemental components. The released atomic gases are next ionized and electrically

charged in a vessel while being subjected to a further energy source that

promotes inter-particle impact in the gas at an increased overall energy

level. Finally, the atomic particles in the excited gas, having achieved

successively higher energy levels, are subjected to a laser or electromagnetic

wave energy source that produces atomic destabilization and the final release

of thermal explosive energy. Engineering design parameters based on known

theoretical principles of atomic physics determine the incremental levels

of electrical and wave energy input required to produce resonance in each

stage of the system. Instead of a dampening effect, a resonant energization

of the molecule, atom or ion provides a compounding energy interaction

resulting in the final energy release.

TABLE I

______________________________________

PROCESS STEPS LEADING TO IGNITION

______________________________________

RELATIVE STATE OF WATER MOLECULE AND/OR

HYDROGEN/OXYGEN/OTHER ATOMS

RANDOM

1st Stage

ALIGNMENT

Water to Gas

POLARIZATION

2nd Stage

MOLECULAR ELONGATION Gas

Ionization

ATOM LIBERATION

3rd Stage

LIQUID TO GAS IONIZATION Priming

ELECTRICAL CHARGING EFFECT

Final Stage

PARTICLE IMPACT

Ignition

ELECTROMAGNETIC WAVE, LASER OR

PHOTON INJECTION

ELECTRON EXTRACTION

ATOMIC DESTABILIZATION

THERMAL IGNITION

______________________________________

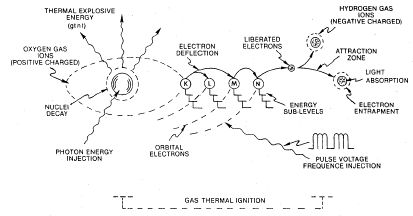

After the first stage in which water is broken down into its atomic

components in a mixture of hydrogen, oxygen and formerly dissolved entrapped

gasses, the gas atoms become elongated during electron removal as the atoms

are ionized. Laser, or light wave energy of a predetermined frequency is

injected into a containment vessel in a gas ionization process. The light

energy absorbed by voltage stimulated gas nuclei causes destabilization

of gas ions still further. The absorbed laser energy causes the gas nuclei

to increase in energy state, which, in turn, causes electron deflection

to a higher orbital shell.

The electrically charged and laser primed combustible gas ions from

a gas resonant cavity may be directed into an optical thermal lens assembly

for triggering. Before entry into the optimal thermal lens, however, electrons

are stripped from the ions and the atom is destabilized. The destabilized

gas ions which are electrically and mass unbalanced atoms having highly

energized nuclei are pressurized during spark ignition. The unbalanced,

destablized atomic components thermally interact; the energized and unstable

hydrogen gas nuclei collide with highly energized and unstable oxygen gas

nuclei, causing and producing thermal explosive energy beyond the gas burning

stage. The ambient air gas components in the initial mixture aid the thermal

explosive process under a controlled state.

In the process, the point of optimum energy-yield is reached when the

electron deficient oxygen atoms (having less than a normal number of electrons)

lock onto and capture a hydrogen atom electron prior to or during thermal

combustion of the hydrogen/oxygen mixture. Atomic decay results in the

release of energy.

In a general outline of the method, a first gas mixture including at

least a portion of hydrogen and oxygen gases is provided. The gas mixture

is subjected to a pulsating, polar electric field whereby electrons of

the gas atoms are distended in their orbital fields by reason of their

subjection to electrical polar forces. The polar pulsating frequency applied

is such that the pulsating electric field induces a resonance with respect

to an election of the gas atom. A cascade effect results and the energy

level of specific resonating electron is increased in cascading, incremental

steps.

Next, the gas atoms are ionized and subjected to electro-magnetic wave

energy having a predetermined frequency to induce a further election resonance

in the ion, whereby the energy level of the election is successively increased.

Electrons are extracted from the resonating ions while such ions are in

an increased energy state to destabilize the nuclear electron configuration

of said ions; and the gas mixture of destabilized ions is thermally ignited.

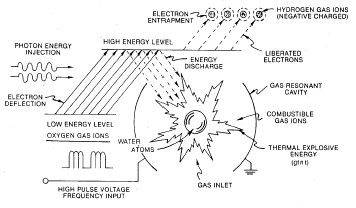

In the apparatus shown in FIG. 1, water is introduced at inlet 1 into

a first stage water fracturing module 2 in which water molecules are broken

down into hydrogen, oxygen and released entrapped gas components by an

electrical disassociation process and apparatus such as shown in my co-pending

application Ser. No. 835,564, filed March 3, 1986, which is incorporated

herein by reference. The released atomic gases and other gas components

formerly entrapped as dissolved gases in water may be introduced to a successive

stage 3 or other number of like resonant cavities, which are arranged in

either a series or parallel combined array. The successive energization

of the gas atoms provides a cascading effect, successively increasing the

voltage stimulation level of the released gasses as they sequentially pass

through cavities 2, 3, etc. In a final stage, an injector system 4, of

a configuration of the type shown in FIGS. 2A or 2B, receives energized

atomic and gas particles where the particles are subjected to further energy

input, electrical excitation and thermal stimulation, whereby thermal explosive

energy results 5, which may be directed thru a lens assembly of the type

shown in FIG. 2C to provide a controlled thermal energy output.

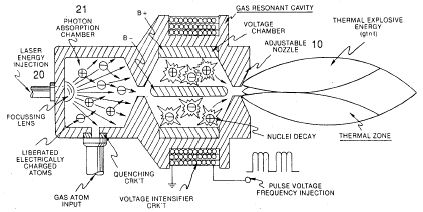

Electromagnetic wave activated and electrically charged gas ions of

hydrogen and oxygen (of opposite polarity) are expelled from the cascaded

cells 2, 3, etc. The effect of cascading successively increases the voltage

stimulation level of the released gases, which then are directed to the

final injector assembly 4. In the injector assembly, gas ions are stimulated

to a yet higher energy level. The gases are continually exposed to a pulsating

laser or other electromagnetic wave energy source together with a high

intensity oscillating voltage field that occurs within the cell between

electrodes or conductive plates of opposite electrical polarity. A preferred

construction material for the plates is a stainless steel T-304 which is

non-chemically reactive with water, hydrogen, or oxygen. An electrically

conductive material which is inert in the fluid environment is a desirable

material of construction for the electrical field producing plates, through

which field the gas stream of activated particles passes. Gas ions of opposite

electrical charges reach and maintain a critical energy level state. The

gas ions are oppositely electrically charged and subjected to oscillating

voltage fields of opposite polarity and are also subjected to a pulsating

electromagnetic wave energy source. Immediately after reaching critical

energy, the excited gas ions are exposed to a high temperature thermal

zone in the injection cell, 4, that causes the excited gas ions to undergo

gas combustion. The gas ignition triggers atomic decay and releases thermal

energy, 5, with explosive force.

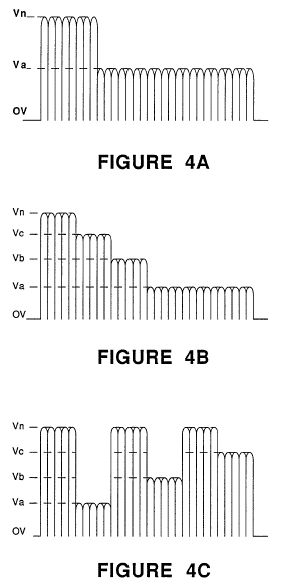

Once triggered, the thermal explosive energy output is controllable

by the attenuation of operational parameters. With reference to FIG. 4A,

for example, once the frequency of resonance is identified, by varying

applied pulse voltage to the initial water fuel cell assemblies, 2, 3,

the ultimate explosive energy output is likewise varied. By varying the

pulse shape and/or amplitude or pulse train sequence of the electromagnetic

wave energy source, final output is varied. Attenuation of the voltage

field frequency in the form of OFF and ON pulses likewise affects output

of the staged apparatus. Each control mechanism can be used separately,

grouped in sections, or systematically arranged in a sequential manner.

The overall apparatus thus includes means for providing a first gas

mixture consisting of at least a portion of hydrogen and oxygen gas. The

gases may be obtained by disassociation of the water molecule. An electrical

circuit of the type shown in FIG. 4 provides a pulsating, polar electric

field to the gas mixture as illustrated in FIG. 3A, whereby electrons of

the gas atoms are distended in their orbital fields by reason of their

subjection to electrical polar forces, changing from the state conceptually

illustrated by FIG. 3B to that of FIG. 3C, at a frequency such that the

pulsating electric field induces a resonance with respect to electrons

of the gas atoms. The energy level of the resonant electrons is thereby

increased in cascading, incremental steps. A further electric field to

ionize said gas atoms is applied and an electromagnetic wave energy source

for subjecting the ionized gas atoms to wave energy of a predetermined

frequency to induce a further electron resonance in the ion, whereby the

energy level of the election is successively increased is an additional

element of the apparatus as shown in FIG. 3D.

An electron sink, which may be in the form of the grid element shown

in FIG. 5A, extracts further electrons from the resonating ions while such

ions are in an increased energy state and destabilizes the nuclear electron

configuration of the ions. The "extraction" of electrons by the sink means

is coordinated with the pulsating electrical field of the resonant cavity

produced by the circuit of FIG. 4, by means of an interconnected synchronization

circuit, such as shown in FIG. 5B. A nozzle, 10 in FIG. 2B, or thermal

lens assembly, FIG. 2C, provides the directing means in which the destabilized

ions are finally thermally ignited.

As previously noted, to reach and trigger the ultimate atomic decay

of the fuel cell gases at the final stage, sequential steps are taken.

First, water molecules are split into component atomic elements (hydrogen

and oxygen gases) by a voltage stimulation process called the electrical

polarization process which also releases dissolved gases entrapped in the

water (See my co-pending application for letters patent, Ser. No. 835,

564, supra). In the injector assembly, a laser produced light wave or other

form of coherent electromagnetic wave energy capable of stimulating a resonance

within the atomic components is absorbed by the mixture of gases (hydrogen/oxygen/ambient

air gases) released by the polarization process. At this point, as shown

in FIG. 3B, the individual atoms are subjected to an electric field to

begin an ionization process.

The laser or electromagnetic wave energy is absorbed and causes gas

atoms to lose electrons and form positively charged gas ions. The energized

hydrogen atoms which, as ionized, are positively charged, now accept electrons

liberated from the heavier gases and attract other negatively charged gas

ions as conceptually illustrated in FIG. 3C. Positively and negatively

charged gas ions are re-exposed to further pulsating energy sources to

maintain random distribution of ionized atomic gas particles.

The gas ions within the wave energy chamber are subjected to an oscillating

high intensity voltage field in a chamber 11 in FIGS. 2A and 2B formed

within electrodes 12 and 13 in FIGS. 2A and 2B of opposite electrical polarity

to produce a resonant cavity. The gas ions reach a critical energy state

at a resonant state.

At this point, within the chamber, additional electrons are attracted

to said positive electrode; whereas, positively charged ions or atomic

nuclei are attracted to the negative electrode. The positive and negative

attraction forces are co-ordinate and operate on said gas ions simultaneously;

the attraction forces are non-reversible. The gas ions experience atomic

component deflection approaching the point of electron separation. At this

point electrons are extracted from the chamber by a grid system such as

shown in FIG. 5A. The extracted electrons are consumed and prevented from

re-entering the chamber by a circut such as shown in FIG. 5B. The elongated

gas ions are subjected to a thermal heat zone to cause gas ignition, releasing

thermal energy with explosive force. During ionic gas combustion, highly

energized and stimulated atoms and atom nuclei collide and explode during

thermal excitation. The hydrogen fracturing process occurring sustains

and maintains a thermal zone, at a temperature in excess of normal hydrogen/oxygen

combustion temperature, to wit, in excess of 2500.degree. F. To cause and

maintain atomic elongation depicted in FIG. 3C before gas ignition, a voltage

intensifier circuit such as shown in FIG. 4 is utilized as a current restricting

voltage source to provide the excitation voltage applied to the resonant

cavity. At the same time the interconnected eletron extractor circuit,

FIG. 5B, prevents the reintroduction of electrons back into the system.

Depending on calculated design parameters, a predetermined voltage and

frequency range may be designed for any particular application or physical

configuration of the apparatus.

In the operation of the assembly, the pulse train source for the gas

resonant cavity shown at 2 and 3 in FIG. 1 may be derived from a circuit

such as shown in FIG. 4. It is necessary in the final electron extraction

that the frequency with which electrons are removed from the system by

sequenced and synchronized with the pulsing of the gas resonant cavity

In the circuit of FIG. 5B, the coordination or synchronization of the circuit

with the circuit of FIG. 4 may be achieved by interconnecting point "A"

of the gate circuit of FIG. 5B to coordinate point "A" of the pulsing circuit

of FIG. 4.

Together the hydrogen injector assembly 4 and the resonant cavity assemblies

2, 3 form a gas injector fuel cell which is compact, light in weight and

design variable. For example, the hydrogen injector system is suited for

automobiles and jet engines. Industrial applications require larger systems.

For rocket engine applications, the hydrogen gas injector system is positioned

at the top of each resonant cavity arranged in a parallel cluster array.

If resonant cavities are sequentially combined in a parallel/series array,

the hydrogen injection assembly is positioned after the exits of said resonant

cavities are combined.

From the outline of physical phenomena associated with the process described

in Table 1, the theoretical basis of the invention considers the respective

states of molecules, gases and ions derived from liquid water. Before voltage

stimulation, water molecules are randomly dispersed throughout water within

a container. When a unipolar voltage pulse train such as shown in FIG.

3A (53a xxx 53n) is applied, an increasing voltage potential is induced

in the molecules, gases and/or ions in a linear, step-like charging effect.

The electrical field of the particles within a chamber including the electrical

field plates increases from a low energy state (A) to a high energy state

(J) in a step manner following each pulse-train as illustrated in FIG.

3A. The increasing voltage potential is always positive in direct relationship

to negative ground potential during each pulse. The voltage polarity on

the plates which create the voltage fields remains constant. Positive and

negative voltage "zones" are thus formed simultaneously.

In the first stage of the process described in Table 1, because the

water molecule naturally exhibits opposite electrical fields in a relatively

polar configuration (the two hydrogen atoms are positively electrically

charged relative to the negative electrically charged oxgen atom), the

voltage pulse causes initially randomly oriented water molecules in the

liquid state to spin and orient themselves with reference to positive and

negative poles of the voltage fields applied. The positive electrically

charged hydrogen atoms of said water molecule are attracted to a negative

voltage field; while, at the same time, the negative electrically charged

oxygen atoms of the same water molecule an attracted to a positive voltage

field. Even a slight potential difference applied to the inert, conductive

plates of a containment chamber will initiate polar atomic orientation

within the water molecule based on polarity differences.

When the potential difference applied causes the orientated water molecules

to align themselves between the conductive plates, pulsing causes the voltage

field intensity to be increased in accordance with FIG. 3A. As further

molecular alignment occurs, molecular movement is hindered. Because the

positively charged hydrogen atoms of said aligned molecules are attracted

in a direction opposite to the negatively charged oxygen atoms, a polar

charge alignment or distribution occurs within the molecules between said

voltage zones, as shown in FIG. 3B. And as the energy level of the atoms

subjected to resonant pulsing increases, the stationary water molecules

become elongated as shown in FIG. 3C. Electrically charged nuclei and electrons

are attracted toward opposite electrically charged voltage zones--disrupting

the mass equilibium of the water molecule.

In the first stage, as the water molecule is further exposed to a potential

difference, the electrical force of attraction of the atoms within the

molecule to the electrodes of the chamber also increases in intensity.

As a result, the covalent bonding between said atoms which forms the molecule

is weakened and ultimately terminated. The negatively charged electron

is attracted toward the positively charged hydrogen atoms, while at the

same time, the negatively charged oxygen atoms repel electrons.

Once the applied resonant energy caused by pulsation of the electrical

field in the cavities reaches a threshold level, the disassociated water

molecules, now in the form of liberated hydrogen, oxygen, and ambient air

gases begin to ionize and lose or gain electrons during the final stage

in the injector assembly. Atom destablization occurs and the electrical

and mass equilibrium of the atoms is disrupted. Again, the positive field

produced within the chamber or cavity that encompasses the gas stream attracts

negatively charged ions while the positively charged ions (and/or hydrogen

nuclei) are attracted to the negative field. Atom stabilization does not

occur because the pulsating voltage applied is repetitive without polarity

change. A potential of approximately several thousand volts triggers the

ionization state.

As the ionized particles accumulate within said chamber, the electrical

charging effect is again an incremental stepping effect that produces an

accumlative increased potential while, at the same time, resonance occurs.

The components of the atom begin to "vibrate" at a resonant frequency such

that an atomic instability is created. As shown in FIG. 3D, a high energy

level is achieved, which then collapses resulting in the release of thermal

explosive energy. Particle impact occurs when liberated ions in a gas are

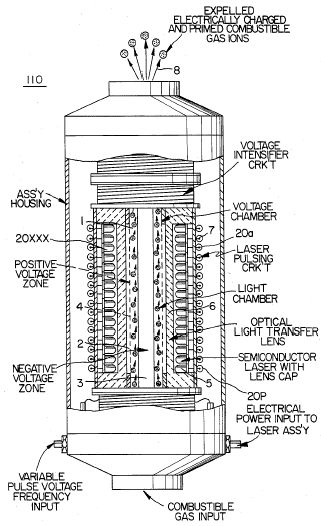

subjected to further voltage. A longitudinal cross section of a gas resonant

cavity is shown in FIG. 2A. To promote gas ionization, electromagnetic

wave energy such as a laser or photon energy source of a predetermined

wave length and pulse-intensity is directed to and absorbed by the ions

forming said gas. In the device of FIG. 2A, semiconductor optical lasers

20a-20p, 20xxx surround the gas flow path. In the device of FIG. 2B, photon

energy 20 is injected into a separate absorption chamber 21. The incremental

stimulation of nuclei to a more highly energized state by electromagnetic

wave energy causes electron deflection to a higher orbital state. The Pulse

rate as well as intensity of the electromagnetic wave source is varied

to match the absorption rate of ionized particles to produce the stepped

incremental increase in energy. A single laser coupled by means of fiber

optic light guides is an alternative to the plurality of lasers shown in

FIG. 2B. Continued exposure of the gas ions to different forms of wave

energy during voltage stimulation maintains individual atoms in a destabilized

state and prevents atomic stabilization.

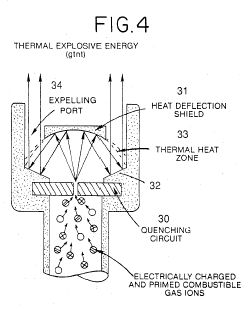

The highly energized gas ions are thermally ignited when said combustible

gas ions pass from injector 4 and enter into and pass through a nozzle,

10 in FIG. 2B, or an optical thermal lens assembly such as shown in FIG.

2C. In FIG. 2C, the combustible gas ions are expelled through and beyond

a quenching circuit, 30, and reflected by lenses, 31 and 32, back and forth

through a thermal heat zone, 33, prior to atomic breakdown beyond exiting

through a final port, 34. A quenching circuit is a restricted orifice through

which the particle stream passes such that flashback does not occur. (See

my application Ser. No. 835, 564, supra.) The deflection shield or lens,

31, superheats beyond 3,000.degree. F. and the combustible gas ions passing

through said exiting-ports are regulated to allow a gas pressure to form

inside said thermal zone. The energy yield is controlled by varying the

applied voltage, or Pulse-train since said thermal-lens assembly is self-adjusting

to the flow-rate of said ionized and primed gases. The combustible ionic

gas mixture is composed of hydrogen, oxygen, and ambient air gases. The

hydrogen gas provides the thermal explosive force, the oxygen atoms aid

the gas thermal ignition, and the ambient air gases retard the gas thermal

ignition process to a controllable state. As the combustible gas mixture

is exposed to a voltage pulse train, the stepped increasing voltage potential

causes said moving gas atoms to become ionized (losing or gaining electrons)

and changes the electrical and mass equilibrium of said atoms. Gases that

do not undergo the gas ionization process may accept the liberated electrons

(electron entrapment) when exposed to light or photon stimulation. The

electron extractor grid circuit, FIGS. 5A and 5B, is applied to the assembly

of FIG. 2A or FIG. 2B, and restricts electron replacement. The extractor

grid, 56, is applied adjacent to electric field producing members, 44 and

45, within the resonant cavity. The gas ions incrementally reach a critical-state

which occurs after a high energy resonant state. At this point the atoms

no longer tolerate the missing electrons, the unbalanced electrical field,

and the energy stored in the nucleus. Immediate collapse of the system

occurs and energy is released as the atoms decay into thermal explosive

energy.

The repetitive application of a voltage pulse train (A through J of

FIG. 3A) incrementally achieves the critical state of said gas ions. As

the gas atoms or ions (la xxx ln) shown in FIG. 3C become elongated during

electron removal, electromagnetic wave energy of a predetermined frequency

and intensity is injected. The wave energy absorbed by the stimulated gas

nuclei and electrons causes further destabilization of the ionic gas. The

absorbed energy from all sources causes the gas nuclei to increase in energy

state, and induces the ejection of electrons from the nuclei.

To further stimulate the electron entrapment process beyond the atomic

level (capturing the liberated electrons during the hydrogen fracturing

process) the electron extractor grid (as shown in FIG. 5A) is placed in

spaced relationship to the gas resonant cavity structure shown in FIG.

2A. The electron extractor grid is attached to an electrical circuit (such

as shown in FIG. 5B) that allows electrons to flow to an electrical load,

55, when a positive electrical potential is placed on the opposite side

of said electrical load. The electrical load may be a typical power consuming

device such as a light bulb or resistive heat producing device. As the

positive electrical potential is switched on or pulse-applied, the negative

charged electrons liberated in the gas resonant cavity are drawn away and

enter into resistive load where they are consumed and released as heat

or light energy. The consuming electrical circuit can be directly connected

to the gas resonant cavity positive electrical voltage zone. The incoming

positive wave form applied to resonant cavity voltage zone through a blocking

diode is synchronized with the pulse train applied to the gas resonant

cavity by the circuit of FIG. 4 via alternate gate circuit. As one pulse

train is gated "ON," the other pulse train is switched "OFF." A blocking

diode directs the electron flow to said electrical load while resistive

wire prevents voltage leakage during pulse train "ON" time.

The electron extraction process is maintained during gas flow-rate change

by varying the trigger pulse rate in relationship to applied voltage. The

electron extraction process also prevents spark-ignition of the combustible

gases traveling through the gas resonant cavity because electron build-up

and potential sparking is prevented.

In an optical thermal lens assembly or thrust-nozzle, such as shown

in FIG. 2C, destablized gas ions (electrically and mass unbalanced gas

atoms having highly energized nuclei) can be pressurized during spark-ignition.

During thermal interaction, the highly energized and unstable hydrogen

gas nuclei collide with the highly energized and unstable oxygen gas nuclei

and produce thermal explosive energy beyond the gas burning stage. Other

ambient air gases and ions not otherwise consumed limit the thermal explosive

process.

Variations of the process and apparatus may be evident to those skilled

in the art.

USP 4,798,661

Gas Generator Voltage Control Circuit

Stanley Meyer

Abstract ~

A power supply in a system utilizing as a source of fuel a generator

for separating hydrogen and oxygen gasses from natural water and having

the capabilities to control the production of gasses by varying the amplitude

of the voltage and/or the pulse repetition rate of the voltage pulses applied

to a pair of plate exciters in a vessel of natural water, comprising a

sequence of circuitry operative to limit the current of a d.c. potential

to a minimum value relative to the magnitude of the voltage applied to

the plate exciters. The circuits each function up to a given magnitude

of voltage to inhibit and curtail the flow of electrons from the plate

exciter having the negative voltage potential applied thereto. The first

circuit operative from a first magnitude of voltage comprises converting

the voltage potential applied to the plate exciters to a unipolar pulse

voltage d.c. of a repetitive frequency. The next circuit varies the duty

cycle of the unipolar pulse voltage d.c.; followed by rearranging the application

of the voltage to the exciters to individual exciters each having the voltage

applied thereto independently of the other plate exciters in the generator.

The next circuit comprises an electron inhibitor that prevents the flow

of electrons; the circuit being in the terminal line between the negative

plate exciter and ground. In those applications of the generator wherein

excessively high voltage is to be applied to the plate exciters for a very

high yield of gasses, a second electron inhibitor of a unique structure

is serially connected with the first electron inhibiter. The second named

inhibiter having a relatively fixed value and the first inhibiter connected

in series is variable to fine tune the circuits to eliminate current flow.

Claims

I claim:

In a generator for producing a mixture of hydrogen and oxygen and other

dissolved gas from natural water which generator includes at least a pair

of plate exciters within a water containing vessel, a variable voltage

source for applying a pulsating predetermined potential difference between

the plates and wherein the rate of production of the mixture of gasses

is controlled by varying at least one of the amplitude of the voltage and

the pulse repetition rate of the pulsating potential difference applied

to the plate exciters.

The variable voltage source includes a means for restricting the current

flow between the plate exciters to a minimum value relative to a predetermined

potential difference applied to the plates, the improvement in the means

for restricting said current flow comprising: variable voltage source means

for converting an input voltage potential to unipolar d.c. voltage pulses

that are applied to the exciter plates and have a pulsating potential difference

when measured from an arbitrary ground.

There is also a means for regulating the voltage pulses in a repetitive

frequency to inhibit the current flow caused by electron leakage between

the plate exciters resulting from the amplitude of the applied voltage

potential whereby said current flow is inhibited from exceeding a first

minimum level.

The input voltage is an alternating current voltage and said circuit

for converting said alternating current voltage to unipolar d.c. voltage

pulses further comprises, means for varying the frequency of said alternating

current voltage input to further inhibit electron leakage upon increasing

the amplitude of the voltage applied to the plate exciters to a second

level.

The variable voltage source is an alternating current voltage for converting

alternating current voltage to unipolar d.c. voltage pulses also comprises

a transformer having primary and secondary windings, and a rectifier circuit

connected across said secondary windings.

The transformer further includes variable inductive means for varying

the output frequency of the voltage induced in said secondary winding to

further inhibit electron leakage upon increasing the amplitude of the voltage

applied to the plate exciters to a third level.

The variable voltage source also has a pulse forming circuit for varying

the duty cycle of the unipolar d.c. voltage pulses to a predetermined repetition

rate to inhibit electron leakage upon increasing the amplitude of the voltage

applied to the plate exciters to a fourth level.

A means is further provided to vary the amplitude of the duty cycle

pulses to vary the rate of production of the hydrogen and oxygen gasses,

further comprising means for correlating the repetition of said duty cycle

pulses with the amplitude of said duty cycle pulses to provide an average

amplitude pulse below the amplitude level causing electron leakage.

The variable voltage source of the generator of claim 5 wherein said

varying of the duty cycle of said unipolar d.c. voltage pulses to inhibit

electron leakage is a periodic varying and aperiodic varying.

It also has circuit means for varying the amplitude of said duty cycle

pulses from a first gradient level to a second gradient level, and a means

for varying the duty cycle pulses to a plurality of distinctive gradient

levels.

It also has circuit means for nonuniformly varying the duty cycle pulses

to a plurality of distinctive gradient levels.

The unipolar d.c. voltage pulses in the duty cycle is non-repetitive.

Varying of the duty cycle of said pulses to inhibit electron leakage

comprise circuit means for varying the amplitude from a first gradient

minimum level to a plurality of gradient levels. Gradient levels of amplitude

represent demand functions for a utilitarian device.

The circuit further comprises means for varying the frequency

of the alternating voltage including a transformer having a primary winding

and a secondary winding, and wherein said means is connected to the input

of the primary of said transformer.

A pair of plate exciters are spatially positioned in natural water with

a physical distance there between of a wavelength to that of a particular

frequency of the voltage back and forth motion between said exciter plates,

and means for varying said unipolar d.c. voltage pulses in frequency to

match the wavelength distance of the pair of plate exciters.

The pair of plate exciters are spatially positioned in the water with

a physical distance there between of a wavelength to that of a particular

frequency of the voltage back and forth motion between said exciter plates,

and pulse forming means for varying the duty cycle of said unipolar d.c.

voltage; and a means for varying said duty cycle pulse in repetition rate

to match the wavelength distance of said pair of plate exciters.

The pair of plate exciters are spatially positioned in water with

a physical distance therebetween of a wavelength to that of particular

frequncey of the voltage back and forth motion between the exciter plates,

and pulse forming means for varying the duty cycle of said unipolar d.c.

voltage ; and a means for varying the duty cycle pulse in repetition rate

to match the wavelength distance of the pair of plate exciters, and means

for varying the amplitude of said duty cycle pulses to a minimum level

to maintain resonance between said pair of plate exciters; and a means

for varying the repetition frequency of said unipolar d.c. voltage pulses

to vary the rate of generation of gasses.

The negative plate has a ground and an electron inhibiting resistive

element connected between the negative plate and ground, providing a means

to vary the resistive element with a variable resistor to maximize electron

inhibition.

The variable voltage source of the generator of claim 28 wherein the

amplitude of the voltage induced in the secondary is dependant on the number

of turns in said secondary winding.

There is a circuit component means for converting an input voltage to

unipolar d.c. voltage pulses of a repetitive frequency to inhibit electron

leakage upon varying the amplitude of the applied voltage above a first

predetermined amplitude level, a pulse forming circuit for varying the

duty cycle of said unipolar d.c. voltage pulses to a predetermined repetition

rate to inhibit electron leakage upon varying the amplitude of the voltage

beyond a second level of amplitude circuit means for varying the frequency

of said unipolar d.c. voltage pulses to inhibit electron leakage upon varying

the amplitude of the applied voltage above a third predetermined level,

a ground and a variable resistive element connected between the plate exciter

having a negative voltage applied it and ground to limit electron leakage

upon varying the amplitude of the voltage beyond a fourth level of amplitude,

a pair of plates and a resistive material sandwiched therebetween connected

to said plate exciter having said negative voltage connected thereto and

the end of the variable resistor opposite to the ground connection, to

limit electron leakage upon varying the amplitude of said voltage applied

to said plates bea fifth level.

Description ~

BACKGROUND AND CROSS REFERENCES

The phenomena of physics was discovered that the hydrogen atoms in the

water molecule will take on a positive charge whereas the oyxgen atom in

the water molecule takes on a negative charge when the water molecule is

exposed to an electrical voltage. The two hydrogen positive charged atoms

and the one oxygen negative charged atoms, in magnitude, are in a state

of equilibrium .

In my co-pending patent application, Ser. No. 302,807, now abandoned

for Hydrogen Generator, the above noted principle of polarization is utilized.

The simultaneous application of a positive voltage pulse to one plate exciter

and a negative polarized voltage pulse to the other plate exciter in a

vessel of natural water, will form polarized voltage electrical zones around

the plates of a respective polarity. The positive voltage plate exciter

zone attracts the negative charged atoms of the water molecule and the

negative voltage plate exciter zone attracts the positive charged hydrogen

atoms of the water molecule.

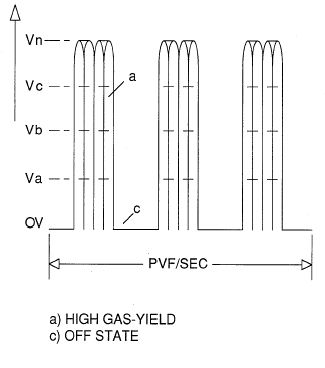

The opposing attractive forces causes the hydrogen and oxygen atoms